NXTdip-150M9

NXTdip-150M9 uses sol-gel method by dipping a substrate into a well of the coating material under controlled parameters to create a thin film of the coating material on the substrate. The sophisticated mechanism and precise controlling by the onboard microcroller ensures acurate results everytime.

Multi-vessel Dip Coating System - NXTdip-150M9

Dip coating is the process of immersing a substrate into a tank containing coating material, removing the piece from the tank, and allowing it to drain. The coated piece can then be dried by force-drying or baking. It is a popular way of creating thin film coated materials along with the spin coating procedure.

Apex proudly launches another state of the art equipment to our Multi Vessel DIP COATING as well as SILAR COATING line-up. Namely the NXTdip-150M9. This low cost instrument has the minimalistic form factor designed to be light weight, versatile and user-friendly. The NXTdip-150M9 is Segmented Dual MCU based system and and ready to meet the Dip coating needs of the scientific community.

Applications

Layer by Layer Assemblies

Self-Assembled Monolayer

Successive Ion Layer Adsorption and Reaction (SILAR) Coating

Sol-Gel Coatings

Glass Stainers for Biomedical Application

Product Specifications - NXTdip-150M9

Segmented Dual MCU based

Dedicated Motor MCU

No. of Vessel Positions: 9

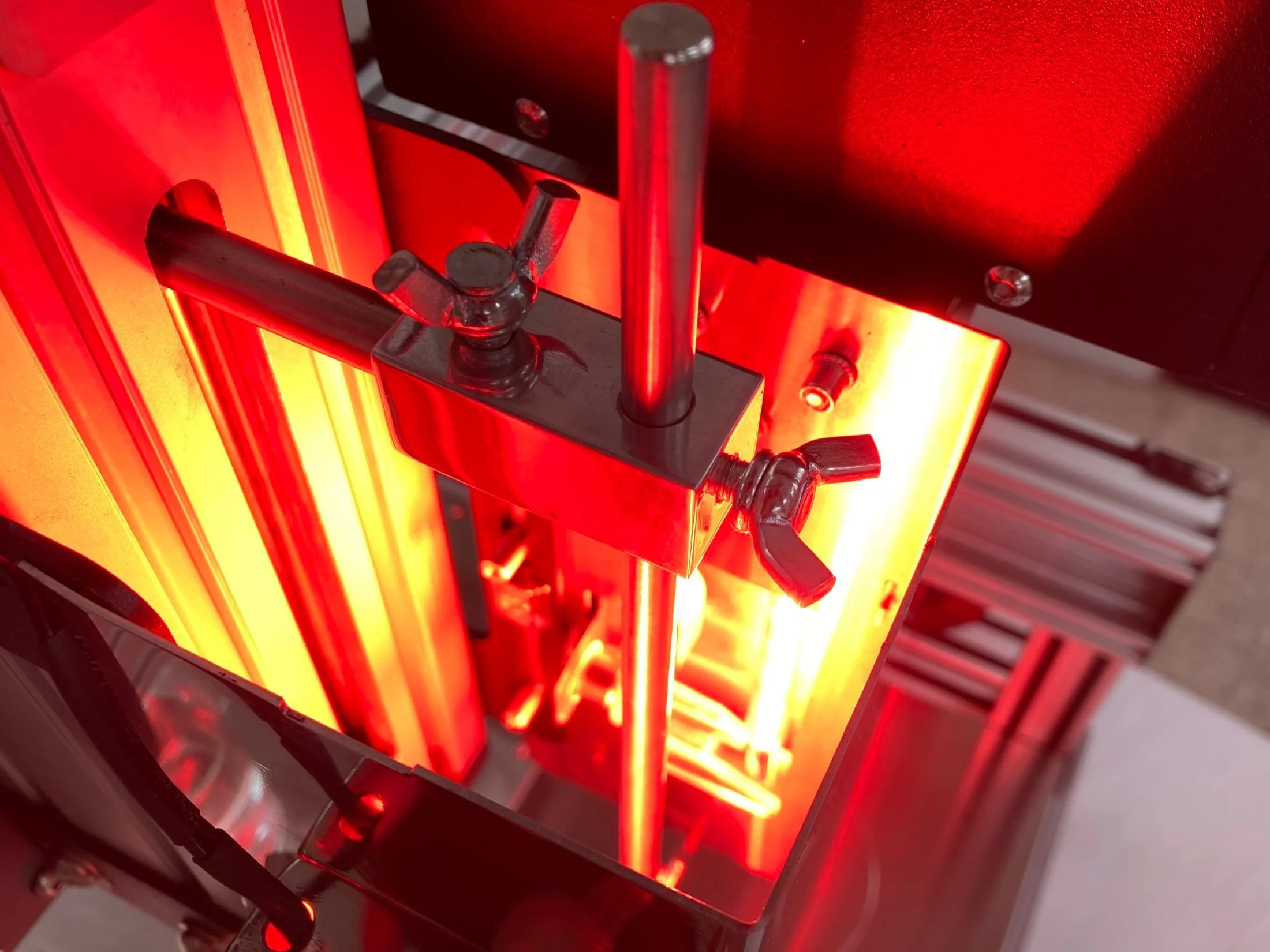

XYZ Axis Gantry System

Dipping & Lifting Speed: 0.15-600 mm/min

Dipping & Lifting Length: 150 mm

Max. Film Length: 100 mm

Unlimited Deposition Cycles

Unlimited Drying & Wetting Time

Non-volatile Program Memory

Input & Controlling through User-friendly PC GUI Interface

Integrated Power On/Off Switch with Indicator

Substrate Mount/Unmount Option

Blank Distance Adjustment Option

Self-performance Test Option

Real-time Display of Control Processes on PC GUI Interface

Display Parameters

Beaker No

Dipping Time

Lifting Time

Blank Distance

Wetting Time

Drying Time

Program No.

Sequence No.

Cycle No.

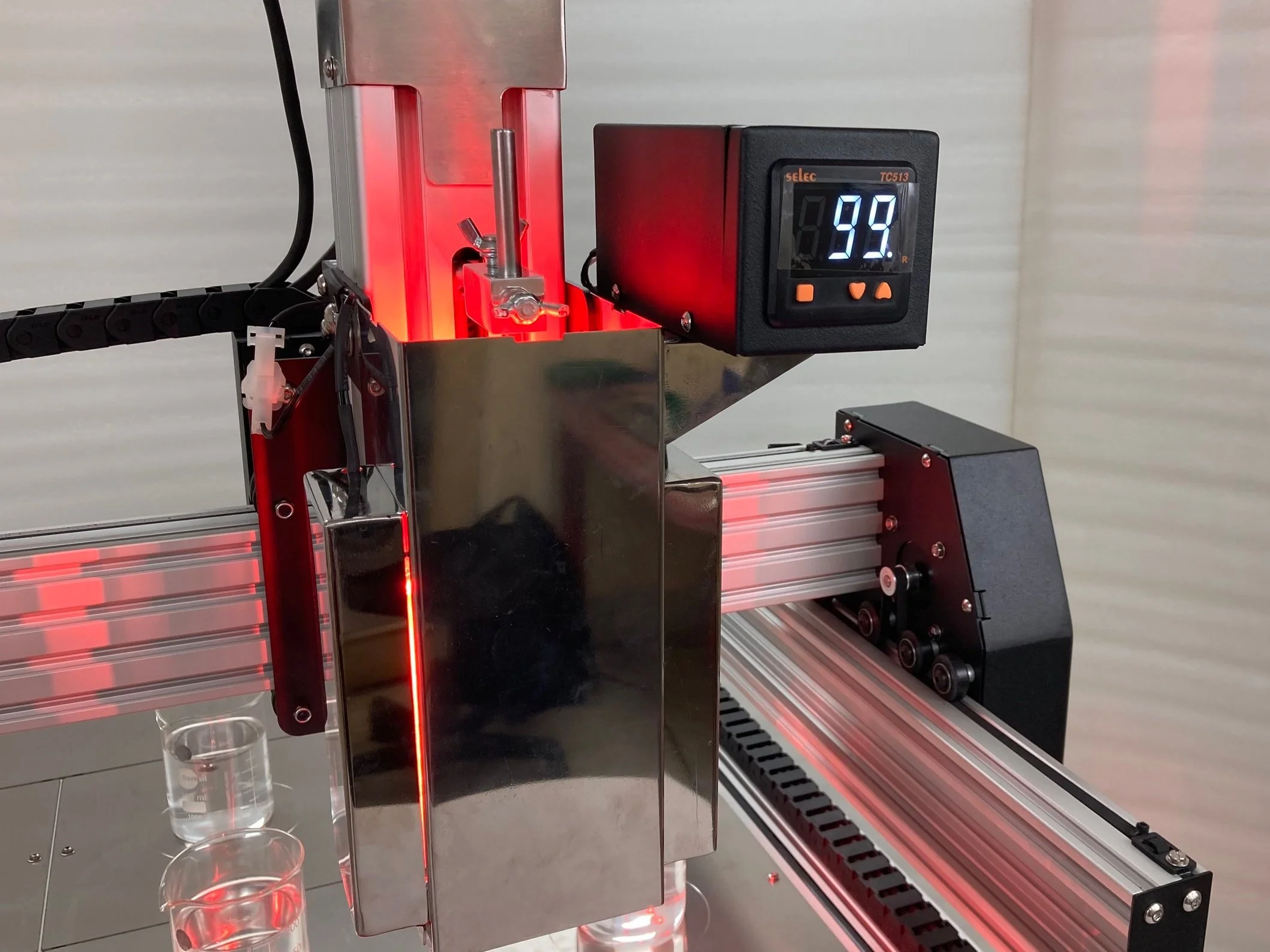

Infrared Substrate Drying (optional with NXTdip-IRM add-on)

Dust-hood for whole system (optional with 150M9-DH add-on)

Power: Indian Standard

Wattage: 120 W (Maximum)

Add-on Modules

NXTdip-IRM - Infrared Substrate heating module, for drying the substrate at temperatures higher than ambient (upto 120 degrees Celsius)

150S-DH - High durability Dust-hood designed specifically for NXTdip-150M9 to fit the whole system in a covered chamber including add-on modules.

Learn more about the NXTdip-150S Dip Coating System in the Product Brochure

How it works Learn more about the Dip Coating Technology under the Technology Info tab